A Berliner Weiss is a German wheat beer that is very low in alcohol and has a very refreshing, almost lemonade-like, sourness. It's a perfect warm weather beer that you can drink just about unlimited quantities of without getting hammered. In other words, it would be a great beer to make and bring to

Odin's Revenge.

So, last Friday Tyler and I brewed... an American wheat beer.

The key to getting the right amount of sourness in a Berliner Weiss (at least the way that has worked for me in the past) is to pitch a large quantity of the bacteria

Lactobacillus at a warm temperature before pitching any ale yeast to let the lacto do it's thing and bring the acid levels in the beer up to where you like it. Then you bring the temp down to an appropriate ale fermentation and pitch your ale yeast. To get enough lacto, I've made 1 liter starters for the lacto and let them sit warm for about a week without any oxygen addition or stirring. I did that this time but something went wrong. Either the vials of lacto,

White Labs WLP677, I got from

Northern Brewer (my favorite local shop,

Patriot Homebrew Supplies, didn't happen to have any lacto on hand at the time) were no good or I screwed something up in my starter prep, because in a week, the pH never dropped much at all. It tasted slightly sour, but I was expecting a pretty good drop in pH and a very tart flavor.

So, plan B it was. I ran back to Patriot to grab a few more pound of malt and a couple more ounces of hops so we could make an American Wheat instead. I ended up using Nelson Sauvin hops for flavor and aroma as they're a hop and I haven't used yet and the descriptors of fruity and white wine flavors sounded like good warm weather flavors.

|

| The drained mash looks kind of like a big round Clif Bar or something. |

I've been playing with no sparge brewing in my last several batches. It saves a bunch of time and hassle since there's no sparge to deal with and doing a mash out step (if you are so inclined) is unnecessary if I put a flame on the wort as soon as I begin collecting it in the kettle. It uses way less propane as well. The downside is that my mash efficiency is significantly lower. When I fly sparge, I pretty consistently hit 80-85%. Back when I used to batch sparge, I got similar numbers to my fly sparging efficiencies. So far, my no sparge efficiencies have been under 65% and rather variable. This batch we hit a whopping 52%! So instead of hitting an O.G. of around 1.045, we got 1.037. That made me glad our mash temperature was a couple degrees higher than the 152° I intended. Hopefully, the higher temperature will give this smaller beer the body it needs. It will be more balanced to the hops than I originally intended, but I'm okay with that.

|

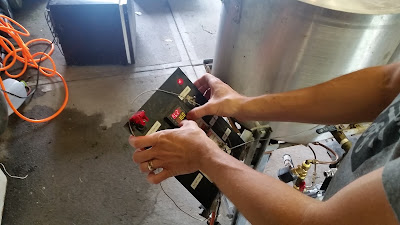

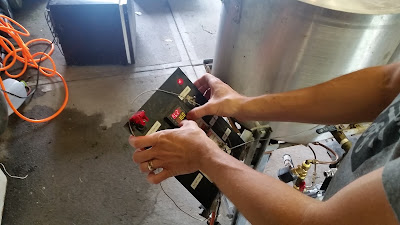

| Automated temperature control. It's the bees knees. |

I know what you more attentive and scrupulous homebrewers are thinking. I should have checked the pre-boil gravity and then corrected using malt extract. Normally I would agree with you, but I was more concentrated on this just being a fun brewday where Tyler and I could just shoot the shit and make some beer while we were at it. So, when the mash temp was a little high, I didn't bother adjusting it and I never worried about checking the gravity until the end. An American wheat beer is a pretty forgiving beer to brew, in my opinion.

So BACK OFF you tubby know-it-all!

Just kidding. You know I'm a tubby know-it-all deep inside too.

|

| Stick a mash paddle in it. |

Flavor-wise, the low efficiency is nothing to worry about, but you need a lot more malt to hit your target gravity which adds cost and, more importantly, takes up more room in the mash tun. I think the next batch I do, I'll try batch sparging again. That will get more of those sugars out of the mash while still being a shorter brewday than fly sparging. I am quite over the novelty of 6-8 hour brewdays.

The brewday was perfect, regardless of the low gravity. We had no random problems and were able to sit back and let the brewstand do its thing while we drank beer and smoked cigars. Good life and bike talk happened which is just about more important than the beer brewing. You can always buy beer, you can't buy the other stuff.

|

| Letting the boiled wort sit hot while the trub settles out in a nice whirlpooled cone. |

Anyway, if you're interested in the recipe, here it is:

Minor Lite Wheat

A ProMash Recipe Report

| BJCP Style and Style Guidelines |

06-D Light Hybrid Beer, American Wheat or Rye Beer

| Min OG: | 1.040 | Max OG: | 1.055 | |

| Min IBU: | 15 | Max IBU: | 30 | |

| Min Clr: | 3 | Max Clr: | 6 | Color in SRM, Lovibond |

| Batch Size (Gal): | 13.00 | Wort Size (Gal): | 13.00 |

| Total Grain (Lbs): | 24.75 | | |

| Anticipated OG: | 1.046 | Plato: | 11.54 |

| Anticipated SRM: | 3.5 | | |

| Anticipated IBU: | 27.5 | | |

| Brewhouse Efficiency: | 65 | % | |

| Wort Boil Time: | 90 | Minutes | |

| Evaporation Rate: | 1.50 | Gallons Per Hour | |

| Pre-Boil Wort Size: | 15.25 | Gal | |

| Pre-Boil Gravity: | 1.040 | SG | 9.90 Plato |

Brewhouse Efficiency and Predicted Gravity based on Method #1, Potential Used.

Final Gravity Calculation Based on Points.

Hard Value of Sucrose applied. Value for recipe: 46.2100 ppppg

% Yield Type used in Gravity Prediction: Fine Grind Dry Basis.

Color Formula Used: Morey

Hop IBU Formula Used: Rager

Additional Utilization Used For Plug Hops: 2 %

Additional Utilization Used For Pellet Hops: 10 %

| % | Amount | Name | Origin | Potential | SRM |

| 18.2 | 4.50 lbs. | Pale Malt(2-row) | America | 1.036 | 2 |

| 3.0 | 0.75 lbs. | Sauer(acid) Malt | | 1.035 | 2 |

| 48.5 | 12.00 lbs. | Wheat Malt | America | 1.038 | 2 |

| 30.3 | 7.50 lbs. | Pilsener | Germany | 1.038 | 2 |

Potential represented as SG per pound per gallon.

| Amount | Name | Form | Alpha | IBU | Boil Time |

| 1.00 oz. | Magnum | Pellet | 12.60 | 23.9 | 60 min |

| 1.00 oz. | Nelson Sauvin | Pellet | 11.60 | 3.7 | 5 min |

| 1.00 oz. | Nelson Sauvin | Pellet | 11.60 | 0.0 | 0 min |

| Amount | Name | Type | Time |

| 0.50 Tsp | Wyeast Nutrient | Other | 10 Min.(boil) |

| 1.00 Unit(s) | Whirlfloc | Fining | 5 Min.(boil) |

Fermentis US-05 Safale American Ale

| Profile: | Distilled Water |

| Profile known for: | |

| Calcium(Ca): | 0.0 ppm |

| Magnesium(Mg): | 0.0 ppm |

| Sodium(Na): | 0.0 ppm |

| Sulfate(SO4): | 0.0 ppm |

| Chloride(Cl): | 0.0 ppm |

| biCarbonate(HCO3): | 0.0 ppm |

| pH: | 8.32 |

| Mash Type: | Single Step | |

| Grain Lbs: | 24.75 | |

| Water Qts: | 40.00 | Before Additional Infusions |

| Water Gal: | 10.00 | Before Additional Infusions |

| Qts Water Per Lbs Grain: | 1.62 | Before Additional Infusions |

| Rest | Temp | Time |

| Saccharification Rest: | 152 | 60 Min |

| Mash-out Rest: | 0 | 0 Min |

| Sparge: | 0 | 0 Min |

Total Mash Volume Gal: 11.98 - Dough-In Infusion Only

All temperature measurements are degrees Fahrenheit.

| Add 3.4g CaCl2 to 10 total gallons RO water in mash tun and 3.1g CaCl2 to 9 gallons RO water in boil kettle. |

Generated with ProMash Brewing Software |

No comments:

Post a Comment